METAL VALVES

METAL VALVES

Ball Valve

When Non-metal soft sealing materials are decomposed by plant fire the ball comes into contact with

the edge of the metal seat of the body and shut off the line, fluid to minimize leakage through the valve

bore.

Ball is heart of ball valves low operating due to smooth mirror surface of ball.

Controlled Sphericity up to 0.00S' assures long life and provide seat high cycle life.

Flexible lip – PTFE seats are located in grooves well protected against damage and cold flow of seal

under pressure. Flexible lip – seats compensate for wear and changes in pressure.

Extended Gland provided for low temperature and cryogenic services to conform requirements

of BS 6364.

Ball Valves with Trunion supported ball having two floating & Spring loaded seats in closed

positions. They provides blockage of flow from both and when the cavity pressure is drained.

- Electroless Nickel coated Balls are also available on request.

- Locking arrangement design on request.

- Gear, Electric Actuator or Pneumatic Actuator on request.

- Sealant In iector desian avail able on request.

- Ring joint Facing available in higher classes.

Applications

- Petrochemical Industries

- Pharmaceutical Plants

- Oil & Gas Industries

- Petroleum Refinery

- Thermal Power Plants

- Fertilizers & Agro Chemicals

- Steel Plants

- Paper Industries

- Cement Industries

- Cryogenic Services

METAL VALVES

GATE VALVE

Meets designs as per requirements of ASME B 16.34 / API 600 /

API 603 / API 6D.

Meets Testing as per requirements of API 598 / API 6FA / ISO 5208.

Out Side Screw and yoke construction.

Valves provided with Backseat arrangement.

Integral Seat design available for only S.S. cast body.

Graphite packings available for controlled clearance between stem,

gland and bonnet bushing for low emissions meet 100 PPM

maximum fugitive emission level.

Anti – Frictional Thrust bearing in yoke sleeve for higher sizes and

classes.

Live 10Mied & Low emission design valves.

Grub Screw: Yoke Nut in bonnet.

G Nipple: Supplies lubricants to the mating parts

Flanged Ends as per ANS' / ASME B 16.6 / DIN / BS 3293 .

butt weld ends as per-ANSI / ASME B 16.25.

to Face ASME ANSI B 16.10.

BI - directional shut-off.

Options

- Self–aligning two piece gland design

- Gear Box / Pneumatic / Rotary Actuator operated valves available on request

- Helium Leak Test shall be provided on request

- Ring joint facing available in higher pressure classes

- Stellited / Hard Facing can be provided on request

- Actual X-Ray of valves can be provided on request

Applications

- Pharmaceutical Plants

- Fertilizers & Agro Chemicals

- Petro Chemical Industries

- Steel Plants

- Oil & Gas Industries

- Paper Industries

- Petroleum Refinery

- Cement Industries

- Thermal Power Plants

- Cryogenic Services

METAL VALVES

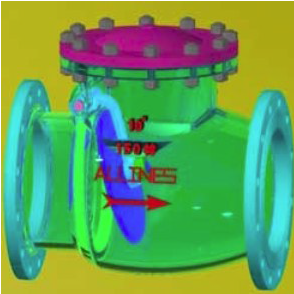

SWING CHECK VALVES

Swing Check Valves used to prevent the reversal flow through pipe lines. These valves are used only for upward or horizontal flow. It offers low resistance to flow and are particular suited to low velocity services.

Disc is opened by line velocity and the resultant pressure. When the flow stops, the disc is closed by gravity. Seating load and resultant tightness are depends up on the back pressure.

The objects of the lever and weight is either to balance the disc or give it added weight. Unbalancing the disc the valve will open with a minimum pressure. When the disc is weighted the valve will be sensitive to reversal of flow.

Incase of intermittent use or in presence of thrusts, dashpot design

is highly recommended.

In such instance the dashpot design gradually causes the opening and

closing of disc preventing, therefore dangerous shocks.

Options

- Ring Joint Facing available on request

- By-Pass and Drain Plug design available on request

- Stellited / Hard Face Seat Rings available on request

- Actual X-Ray of valves can be provided on request

Applications

- Pharmaceutical Plants

- Petro Chemical Industries

- Oil & Gas Industries

- Petroleum Refinery

- Fertilizers & Agro Chemicals

- Steel Plants

- Paper Industries

- Cement Industries

METAL VALVES

GLOBE VALVE

The Globe Valves derives its name from the globular shape of the valve body. This type of valves suited both general and throttling flow control. Where the valves is normally closed and pressure drop is not important when valve is in open condition.

Meet design requirements as per BS 1873 / ASME / ANSI B 16.34.

→ Meet testing requirements as per BS 6755 / API 598 / ISO 5208.

→ Outside screw and yoke construction.

→ Graphite packings available for controlled clearance between stem, gland

and bonnet bushing for low emissions meet 100 PPM maximum fugitive

emission level.

Anti-Frictional ball thrust bearings in yoke sleeves for higher sizes

and classes.

→ Flanged Ends as per ANSI / ASME B 16.5 / API 605 / DIN / BS 3293.

→ Butt Weld Ends as per ANSI / ASME B 16.25.

Face to Face dimensions as per ASME / ANSI B 16.10 / DIN / BS 2080.

→ Uni- directional shut-off.

Options

- Extended Bonnet provided for low temperature and cryogenic services as per BS 6364 requirements

- Deep stuffing box with lantern rings available on request

- Helium Leak Test shall be provided on request

- Gear Box / Electric / Pneumatic Actuator / Chain Wheel design available on request

- Locking arrangement / By-Pass arrangement available on request

- Stellited / Hard Face Seat Rings available on request

- Actual X-Ray of valves can be provided on request

Application

- Pharmaceutical Plants

- Fertilizers & Agro Chemicals

- Petro Chemical Industries

- Steel Plants

- Oil & Gas Industries

- Paper Industries

- Petroleum Refinery

- Cement Industries

- Thermal Power Plants

- Cryogenic Services

METAL VALVES

LIFT CHECK VALVES

Lift Check Valves are designed to be opened by the flow of system pressure in one direction and closes automatically when the system flows in opposite direction. A piston to dump the disc during operation.

Ring joint Facing available on request.

→ By – Pass and drain plug design available on request.

Stellited / Hard face Seatrings available on request.

Actual X- Ray of valves provided on request.

Applications

- Pharmaceutical Plants

- Fertilizers & Agro Chemicals

- Petro Chemical Industries

- Steel Plants

- Oil & Gas Industries

- Paper Industries

- Petroleum Refinery

- Cement Industries

- Thermal Power Plants

- Cryogenic Services

METAL VALVES

TIL TING DISC CHECK VALVE

Til Ting Disc Check Valves are used to prevent reversal of flow in horizontal or vertical pipe lines. In vertical pipe lines or any angle from horizontal to vertical. They can be used for upward flow only. Til ting Disc Check Valves are similar to Swing Check valves. In most installations, slamming is minimized upon reversal flow. So, noise and vibrations are reduced.

Til Ting Disc Check Valves consists of a cylindrical housing, with a pivoted

circular disc. The pivots are located just above the center of the disc and

offset from the plane of the body seat. This design gives a bell – crank

action to the disc. The seat is circular bevel type and the disc drops in out

of contact without rubbing or sliding.

Short distance of travel, combined with a balanced disc allows rapid

closure while minimizing slamming.

Drop tight seating is accomplished over the full pressure range because

a slight clearance at the pivot pin assures complete seating between the

disc ring and body ring.

The full flow area with lower head loss ensure with the highest efficiency and durability.

→ Meet design requirements as per API 6D / API 594 / BS-EN 12334 / API B 16.34

- Meet Inspection requirements as per API 598 / API 6D.

- Face to Face dimensions as per API 6D / API 594 / ANSI B 16.10

- Flanged Ends to ANSI B 16.5 / B 16.47.

Options

- Single Switch / Hydraulic Cylinder (top, bottom and side mounted) design available on request.

- By — Pass arrangement available on request.

Applications

- Suitable for all types of water, air and steam 1210C or 2500F (For higher temperature, consult factory).

METAL VALVES

1 PC. DESIGN KNIFE GATE VALVES

→ Meets design testing standard as per MSS-SP-81 for fully lugged Knife Gate Valves.

→ Bolted body and yoke bonnet for easily maintenance.

Outside screw and yoke construction with thrust bearings.

Designed to handle slurries, pulp stock and corrosive fluids

in process industries.

“Allines” high quality metal seated Knife Gate Valves with

ground knife gates and lapped seating faces have allowable

permissible leakage rate.

Equally gland follower provide uniform compression of packing.

Body:- MSS SP-81 requires the valve body to be designed for and

hydrostatically pressure tested to 1.5 times the rated working pressure.

Full Bore design if required

Flow Directions

- Metal Seated Flow : Uni–Directional Flow

- Soft Seated Flow : Bi–Directional Flow

- Larger size and customized design valves available on request

- Full port valve offers minimal resistance to flow and smooth operation even during frequent valve actuation

Options

- -5 Design available with chain-wheel, Gear, Electric — Pneumatic or Hydraulic Actuator.

- Locking arrangement on request.

Applications

- Mining, Power, Pulp and paper, Alumina, Chemical, Cement.

METAL VALVES

Dual Plate Check Valve

“Dual Plate Check Valve” is an all purpose Check Valve

(NRV). The Valves are designed to API 594 and comply with

API 598 Valves inspection & testing standard. This design has

distinct advantages over conventional Swing Check Valve or

any single disc design

Stronger, Lighter and Smaller size. it weights about 1/5th weight of

conventional valve

Flexible installation: Can be installed in horizontal or vertical line

without any special pipe support.

Salient valve – Water hammer & Slamming almost eliminated

• Low pressure Drop hence lover energy loss

- Body & Plates : C.I./C.S./S.S./ALLOY STEEL/AL. Bronze to A-216 Gr. WCB, CF8, CF8M, LCB, B.S.1400 AB 2 OR any other alloy as per Buyer’s specifications

- Hinge & Stop Pin : Stainless Steel or Bayer’s specification

- End Facing : Plain Face, Raised Face or Ring Joint Facing

Applications

- Water

- Air

- Oil

- Steam or any other process fluid

METAL VALVES

Y-Type STRAINER

“ALLINES” provides a comprehensive range of manual pipeline Strainers.

Pipe strainers are offered in a wide choice of size & MOC with various end

connections, pressure rating up to class 600.

“ALLINES” Name synonymous with quality commitment to quality, customer

satisfaction and continual improvement is integral to our manufacturing

process and ensures custom engineered strainer meet our design

specification and stringent quality requirements. We have made it easy for

you to place order with confidence.

• “ALLINES” also makes “Y” - Type, Pot (Basket) Type, Simplex Type,

Tee Type strainers with custom engineered fabricated strainers to

many design codes for a variety of applications.

- Drain / Vent arrangement on request.

- Remove foreign particles, debris, lumps etc.

- Can be installed in either horizontal or vertical position

Typical Usage Industries

- Water Handling

- Marine Industries

- Paints

- Electric Utilities

- Cosmetics

- Petroleum

- Paper

- Transportation

- Power Plants

- Allied Industries

- Food Industries

- Process Equipment

- Ink & Latex

- Pharmaceuticals

- Refrigeration Plants

- Pulp

- Ceramics

- Chemical Processing

- Petrochemicals

METAL VALVES

Wafer Type Swing Check Valve

The disc design can swing freely within piping system interference with

the inside diameter of the connecting pipe lines allows to suit both

ASME 150# & DIN PN -10 / PN -16 Flanges.

These valves can be used in horizontal and vertical installations

against the disc to achieve a seal : Open / Close positions within pipelines.

• A valve that is designed to allow the fluid to flow in a given direction

but closes to prevent back flow. Check valves are usually self acting.

Testing Standard as per BS - EN 12266 - 1 / DIN – EN - 588 – 1

- Size Range : 1”NB to 24”NB

- • Body & Disc Material : S.G. Iron (NOD CI) / WCB / CF8 / CF8M / CD4MCu

- • Temperature Range : -60 °C to +200 °C

Applications

- Industrial Inorganic Chemicals

- Plant Protective Agent Production

- Detergent Production

- Bromine Production

- Nitrogenous & Phosphorus Fertilizers

- Pharmaceutical Preparations

- Petroleum Refining

- Industrial Organic Chemicals

- Alkalis & Chlorine

- Water Treatment

- Sulfur Recovery

- Food Processing

- Sugar Industries

METAL VALVES

HEAVY DUTY SLUURY KNIFE GATE VALVES

Flexible pressure assisted two-piece rubber sleeve system allows valve to cycle in heavy slurries without sticking .

Sleeves are easily replaced without disassembling the valve .

New and replaceable upper seal design is not only packing less, which eliminates the need for periodic adjustment, it is also a self lubricating system and is rechargeable without valve disassembly.

Bi-directional full port flow reduces pressure drop and turbulence, thus minimizing wear.

Flushing plate option allows for periodic cleaning of the lower discharge vent and allows flushing as needed.

Two – Piece Rubber Sleeve System

- Port pressure provides assistance by forcing the sleeves against the opposing sleeve or the gate, depending on the position, to provide greater sealing force. Face rings allow the valve to cycle under maximum flow conditions up to a maximum differential of 150 psi/10 bar.

- Seats are self gasketing and are compatibility with raiseface.

Open Bottom

- Open bottom allows for the purging of large solids, and solids in higher concentration. The purging of solids stops when the gate is in the full open or closed position.

Flushing Cover Bonnet

- Flushing Bonnet attached to the bottom flange to capture any discharge during cycling.

- This option also allows for periodic cleaning of the lower discharge vent and can allow flushing as needed.